Video Transcript

0:27

you

0:32

now see people already starting to answer polls we appreciate it some of the questions we’re asking about

0:37

is is how you use your elbrick planting scripts do you use them can you get an

0:43

ROI and what is kind of holding you back from using variable rate planting more

0:51

I’ll give a little bit of discussion about this as people are cutting it in currently we have the predominance of

0:58

the people so far about 70% currently use variable like planting scripts but

1:03

there’s there’s still 30 to 40 that people say they don’t use very bright

1:08

planting scripts on there or their clients as growing operations

1:14

as we move on to the next question we asked who who is creating the variable

1:20

rate scripts a very high percentage third percent are personally creating them and then about about 50% use either

1:32

an opinion are independent agronomists and then a very significant portion also

1:38

about 30% say they use some type of a green tail so it’s a good mix between independent agronomists growers

1:45

personally creating them or a use of a greet ale and then we ask we’re asking

1:52

you know do you know that you make a positive ROI which is kind of the core of this our webinar today and about 60%

2:01

don’t know for a fact that they can show part of the positive ROI probably like why we’re on this webinar today a good

2:08

30% are fairly confident that they have a positive ROI and then there’s about 10 to 20% they just don’t know and then we

2:17

ask what is holding people back from using very ROI planting more very high

2:23

percentages are still having hardware challenges about 40% still say that hardware challenges are holding them

2:29

back 20% saying they just don’t have enough time to do it all and then

2:36

there’s there is about 30% saying available knowledge base is holding them back definitely you benefited the

2:43

webinars like today and then very at least half that people are saying the

2:49

ability to prove a positive ROI is holding them back and then kind of the

2:54

crux of the whole webinar today is if you could show a positive ROI would you would you use it more and a predominant

3:01

70% are saying yes and 25% are saying maybe and that’s that’s kind of what

3:09

we’re working on today is assembling people how understand how to do that I’ll let this poll go for a little bit

3:14

longer we still have probably 30% haven’t answered the poll yet so we’ll just keep

3:20

this going a little bit more I’m gonna explain zoo if you’ve never used them before just move your mouse around and

3:27

you’re probably gonna have a black bar either at the top of the bottom of your screen and as you move your mouse around

3:32

that’ll come up and that’ll tell you you’ll see then a Q&A button you’ll

3:38

probably see a chat button also so you let’s use the chat function if we’re

3:43

just making a general comment as we progress through this webinar you need a general statement like hey you need help

3:48

with something there’s also another section for the QA and if you have questions that you

3:55

specifically want the panelists to answer then type your questions in there and at the end of the webinar we will do

4:02

our absolute best to get through every one of those q and A’s that go into that QA section there and we’ll specifically

4:09

answer it that’s that’s very helpful for us and if you have questions as we go

4:15

through go ahead and type them in there we may not answer our way but we’ll hit it as we get to the end of the webinar

4:27

you so as we sent out the the calling for

4:33

this webinar today we said some topics that we’re going to cover at war how to set a variable rate plan to script for

4:39

your field what data layers should you use to set those planning scripts

4:45

how to get insights of you’re planing scripts and then we were going to show you some examples of ry+ planing scripts

4:54

and I am absolutely confident that Carlin Mike will be able to take us through that today and then we will

5:00

address those four questions as we move into the question and answer section so with that I’ll introduce myself again my

5:06

name is Scott Jackman from Devron I run US operations and wheels also the sales and marketing effort also with us today

5:14

is Mike Wilson and I’ll hand over to Mike Wilson for introduction of yourself

5:19

morning everyone Mike Wilson data collections lead for Devron UAS and agronomist with Veritas

5:27

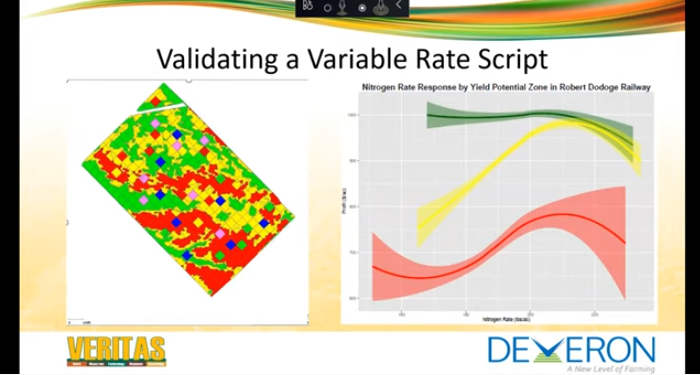

work in the precision AG industry for almost 18 years now validating scripts

5:35

and creating success for customers has been a real passion of mine from the beginning working with the Veritas team

5:42

has brought us to new levels with the way we can analyze and statistic would

5:48

be analyzed the data to come up with some results and look for those successes something that I wasn’t able

5:55

to find elsewhere in industry at the time so wanna happy to work with Carla here today throughout this presentation

6:01

and answer any questions you may have to show kind of the steps we take to do that and help you guys learn more from

6:08

from the scripts you’re writing and make better decisions on the farm as we plant and get into this 2020 season yeah

6:18

thanks Mike and with that I’ll hand it over to Carla Carla Jackson is gonna lead us through the webinar today and

6:25

Karl if you would take over screen and I have stop sharing and the screen is now

6:30

yours Carla introduce yourself and let’s begin if we can okay great thanks Scott

6:36

can you guys see my screen okay can you hear me all right we can see your screen and hear you well thank you okay perfect

6:43

all right good morning and thank you everyone for taking the time to join us today I am Carla Jackson I am the market

6:52

development agronomist with Veritas here in Chatham in southwestern Ontario um

6:58

today we are going to be a Scott mention and and Mike I’ve mentioned we’re going

7:04

to be discussing variable rate planning prescriptions what you need to get started why validate them and some of

7:11

the return on investment and analysis that can be provided from the prescriptions when considering utilizing

7:20

any decision AG solutions there are four areas that you must look at that are important to ensure that the applied

7:27

methods are working for you the first one is to identify we want to identify

7:32

issues in your field whether it is nutrient deficiencies through soil sampling doing research plots or just

7:40

your knowledge of the field that certain areas are not growing the same as others once you’ve identified that issue what

7:47

do you want to do next you want to measure you want to measure those differences with imagery adjusting your

7:53

crop plans or creating management zones to help start tracking the differences so you can approve them effectively you

8:01

then want to manage those differences that you have measured by scouting those specific areas collecting and recording

8:08

the data for those areas and by writing prescriptions based on the management

8:13

zones that you have created you can start treating those areas individually with planning prescriptions fungicide or

8:19

fertilizer prescriptions finally you want to validate that you’re managing

8:25

those areas efficiently and effectively by putting check blocks or we call them

8:31

Vera blocks in your prescriptions regardless of what applying you can analyze the application you can also

8:38

create profitability maps that break down your efficiencies and your return on investment in each management zone

8:44

they can show you the areas that you need to increase or decrease seed input

8:50

costs etc to break-even by validating your inputs you can also start to

8:57

identify other areas that need adjusting and you can apply these four steps many

9:03

companies today offer one or two of these steps precision area companies can offer three of these steps

9:10

but as an industry we’ve done a poor job too at showing the validation so the

9:17

point of today is to show how to better validate your fields and learn from your prescription to make better decisions

9:23

moving forward today we’re going to

9:28

focus on using planning prescriptions and validating them to choose the optimal planning rate and also using

9:35

prescription insights to dive deeper into understanding our varieties and improving our deficient areas the most

9:45

popular question that many ask is how do I get started and or what data lay

9:51

layers do I need to get started you can work with your hieronymus to pull this data together or or to see what layers

9:58

you have or you don’t have to start collecting and how the data layers that

10:04

you need to start creating and using planning prescriptions is historic guilt or normalized yields you can use NDVI

10:12

imagery you can use soil zones ones that you have used in more recent years you

10:18

can use bare ground imagery you also need a digital boundary we’ll also need

10:25

the planter width and the combine width this information is used in the creation

10:30

of the check blocks so those are sure to fit to your equipment and it’s easier

10:36

for your monitor to follow we’ll also need the planner monitor and the tractor

10:42

does it have the ability to control the rate the make and model are also

10:47

important to ensure that the prescriptions are created in the proper format that works with your monitor if

10:53

you have if you just need basic shape files and we send you a task controller

10:59

file those aren’t going to communicate so we want to make sure that you have the right format for your prescription

11:05

right off the bat so they can start working together quick and easy we’ll

11:10

also need the a B lines so the tractor guidance so we can make sure that the script is lined up with your tractor

11:16

guidance so where your where you they’re planning is where your prescription will start once you’ve

11:25

verified that you have some or all of the required layers then we can start to make the planning prescription Fairbury

11:33

prescriptions can be based on yields at least three to four years is preferred but one year can be used for growers

11:40

just starting out we then can create three or four crop production zones created based on your yield performance

11:47

and other characterizing features like low yield the medium to low yield the

11:53

medium to high yield and the high yield prescriptions can also be created off

11:58

bare ground imagery soul zones or NDVI crop health imagery sometimes all are

12:04

used you can see on this map the larger one here the zones are based off a

12:10

normalized yield at the top right the zones are created off a one-year yield and the bottom right is a satellite

12:17

imagery and you can tell that the soil color and the type is quite indicative

12:23

of its impact on the yield those zones all line up fairly well once you choose

12:30

the most representative image a prescription can then be created when making a script your seeding rates

12:36

should be discussed with your agronomist once you have decided your rates based on your fields variability and variety

12:43

they’re assigned to corresponding production zones for instance if you’re planting corn you’ll want to put your

12:50

higher seeding rates in the high yielding zones and for soybeans or edible beans you’ll want to put your

12:56

high seeding rates in the low yielding zones this is to increase the yield and

13:01

those low areas but also to control the white mold risk and those high yielding zones the lower population if it was

13:09

more plant space equals less disease risk this field for example has a huge

13:16

variability and that’s why there’s a large spread in the seeding rates of 28 to 38 thousand if your field doesn’t

13:23

have a large amount of variability your range and raids can be tighter it could be 32 34 36 32 36

13:32

32 to 38 depending on your soil type and your variability these are also the

13:39

standard rates to start out with when trying planting scrape scripts knowing the different areas of the field

13:46

and the varieties you’re using is very important you can also work with your local seed rep to get the optimal seed

13:54

rates of the varieties that you’re planting and also to find out the varietal response from variable rate to

14:00

help you get started once the rates have been assigned ver blocks or check blocks

14:07

of higher and lower seeding rates are added to each yield zone for validation after harvest this process is a very

14:14

very important to validate and learn about optimizing your seeding rates to

14:21

improve the efficiency I also just wanted to note that it’s also possible

14:26

to add ver box to any scripts so if you want to create your own script that is

14:32

great like you can create your own zones you can apply your seed units that you want to follow we can then add the check

14:39

blocks to your script and then for the final prescriptions so you can send any

14:45

in any prescription and then we can just add in those the variable ox for the analysis at the end of the season fare

14:56

box or checkbox allow for plot research on the on the field scale check box do

15:03

not require extra work for the grower especially in the busy season the monitor does all the work this allows

15:09

for the farmer to plan the field in one pass to combine and harvest in one pass

15:14

there’s no way weighing and required or extra work you get tons of data and analysis to learn from it takes a little

15:22

extra work in the in the winter for planning but that helps you to ensure

15:27

that there’s less work when it’s in the busy season bear walks can also provide

15:35

insights to what the ideal target rate for each yield zone is your return on investment and also a variety comparison

15:43

within the field which variety performs best in each production zone and what rate is

15:48

optimal here are two examples of plenty

15:55

of prescriptions with fare blocks on the left is a corn script where you can see

16:00

that the high production zones and rates are within the fields and the low production and rates are typically head

16:06

lands on the top of the nulls this grower planted 31 to 38 per acre so

16:13

they have four production zones a low and high outlier seeding rate is added

16:19

so you can compare the lowest actual seeding rate to array above and below and same for the highest actual seeding

16:26

rate this is so at the end of the season you can compare what rate perform the best and maybe they need to decrease the

16:34

rates or up them on the right is a soybean script the highest production

16:41

zones are the slowest seeding rates within the field and the higher seeding rates are on the headlands and nulls

16:49

this field has a bit of variability in the rates range from 145 to 205 with two

16:58

outliers seeding check blocks you can see that the grid pattern that’s

17:04

overlaid on the field is set to the equipment size and then we put in the different check blocks in each

17:10

production zone this orange zone here it’s the 31,000 seeding rate and you can

17:17

tell see that there are six red blocks which is the 29,000 seeding rate and

17:23

there are six yellow blocks of the 33,000 seeding rate all on that same zone so this forces the equipment to go

17:30

higher and lower so you can actually analyze what the optimum rate was for this production zone

17:38

we also use your a B lines or your guidance lines you put towards the

17:43

straightest side of the field so we can make sure that the script is actually lined up with the areas that with the

17:49

area that you’re going to start planning first you can see that in both examples here I can I will now go through a

18:01

couple examples of how the process works start to finish the planning

18:06

prescription was created based on yield and this script is for soybeans so these

18:11

sign rates as discussed with the grower are placed in the appropriate zones the

18:18

very box are then placed randomly throughout each production zone so you can see that the lowest seeding rate a

18:24

large check block of 135 was placed throughout the 145 production zone once

18:31

the script is reviewed and approved the grower will get a PDF copy so they know

18:37

the total amount of product needed and their target rates the appropriate format for the script is then exported

18:43

and loaded to the growers monitor when you’re planning please ensure that the

18:49

right fields prescription is activated and on and then let the monitor and the rate controller do all the work the

18:59

middle map is what the planning as applied map looks like you can see where the planner increased and decrease the

19:05

rates throughout the fields the yield map on the right shows a high yielding

19:12

areas corresponding with the lower rates we know the zones are correct but the

19:19

rates need some adjusting these three layers the prescription the as applied

19:25

and the harvest maps are used in the end of season analysis

19:33

the value of having check blocks is being able to see what you plan it and a profit made the check blocks compare and

19:41

show you if you planted a higher or lower seeding rate and what would your ROI be so when we look at these graphs

19:55

here on the page we I would say this is a very good set an example to use for

20:01

what you would see likely in your first or second year of trying some various eating prescriptions as Karla mentioned

20:09

how we set the rates up and and how we filled the prescriptions is key to being able to produce curves like this and to

20:15

be able to do this statistical analysis to give us enough data on what the results begin to look like so the graph

20:22

in the top left is a typical response we see from a corn hybrid and the graph we

20:29

have in the bottom right is what we see kind of in the first year approach with a soybean customer so generally we see

20:37

here the three or four different production zones labeled by color so the

20:42

in the top left graph the red line is the low producing areas of the field

20:49

obviously profit per acre on the Left axis shows us that the mid-range is our

20:57

medium or average producing areas and that’s the yellow color and our high producing yield areas our most

21:02

profitable areas in the field are represented by the green curve the solid line in the middle of the curves

21:08

represents the average of the data or the line of best fit the shaded area or

21:15

the light green or yellow or red areas represents the spread in the data or

21:21

some like to say the confidence interval in the data so the wider the spread the thicker the line the more variability we

21:28

have either due to zones or due to fried your performance or whatever have you if it’s a little bit of noise in the data

21:34

and the less predictable the the end result would be of the lines but nonetheless when we look at these two

21:40

graphs we start to see some really interesting trends that make sense economically and really help the

21:45

customer and the agronomist makes smarter decisions moving forward on this farm the hashed mine or dashed line that

21:52

goes vertically is the average rate of the planning script or let’s say the

21:58

average seeding rate the customer would have planted had he done a straight rate application in the field so right away

22:04

you can see in the red area on that on that corn graph if you would have planted the thirty four thousand seeds

22:11

breaker that is the profit breaker you would have made by planning less seed he was actually more profitable and by the

22:18

looks of that curve could have been even more profitable had he planted less yet when we look at the yellow line he’s

22:25

fairly close to the top of that curve and that makes sense ager anomaly I mean the historic average

22:30

seeding rate for your average field numbers should be pretty close to that most profitable area in the average of

22:37

that field and it is showing that that is accurate pretty accurate on that farm when we go into our high-yield zone the

22:44

green lining we can see where we would have been at the average seeding rate and as we move to a higher population

22:52

profitability goes up this script did make the customer some money in the zone but there’s potential to increase

22:58

seeding rate farther for even more profit so we learned two things you know

23:03

or at least two things from this information we learned that yes the script was profitable yes the customer made the right decision and that variety

23:09

did respond and we also learned that there’s potential to maybe push this a little bit farther as we move into three

23:16

years if that is shows the same trend over time when we look at the soybean map in the bottom right corner we have

23:23

the same scenario in the same way of reading the curves but we get a little different aspect on on the end result

23:29

and the seeding rate that was chosen in the field so again if we look at that horizontal or the vertical dashed line

23:35

we see our average seeding rate in that field would have been about a hundred and seventy five thousand seats breaker

23:46

when we look at the curves themselves also we see the blue line being our lowest yielding areas with our highest

23:54

seeding rate it’s the opposite of corn in order to try to promote

24:00

more vegetation more seats breaker stronger crop growth so on and so forth

24:07

and then on the other end of the spectrum the red line being our highest yield environment most profitable area

24:12

where we apply the lowest seeding rate because we get naturally good growth we get excellent germination risk of

24:19

disease is higher so on and so forth so when we start to analyze the other set of curves we can see that the blue line

24:27

is actually most profitable right at that 175,000 seeds breaker that the

24:34

customer planted as is average and if we think about that in the real world why do our customers plant 175,000 seeds

24:40

breaker in a field it’s usually because we want to ensure that that 5 acres in

24:45

the back corner that’s usually tough and in under poor conditions just won’t come up or won’t perform if we don’t plant

24:52

that many seeds so we wind up sacrificing the profitability across the rest of the farm based on the worst

24:58

areas of the field so when we look at this graph we can see we should have planted 175,000 in that poor yield

25:05

environment we should have planted less than that and the green yeah as we move

25:11

to the left we get more profitable the yellow is showing the same trend it made

25:16

us money from the average but we should have planted less again and the red line showing the exact same trend also so the

25:23

what we see on this is yes the script made the customer money but at the end of the day having planted twenty five

25:29

thousand seeds break or less still in a variable rate situation would have made him even more and had made him more

25:36

profitable

25:45

so this is a paper report we can give back to the customer at the end of the

25:50

season we do supply that graph that we just reviewed this is the actual soybean field that we were discussing in that

25:57

graph but we also give where the profit was actually made in the field in the in

26:02

the map in that top left corner and how each zone performed profitably and we

26:08

also give some statistic numbers at the bottom so that script itself made the customer seven dollars and 33 cents

26:14

compared to what the data is telling us he would have made had he planted that straight rate 175,000 seeds breaker so

26:22

the total profit of that field was about four hundred and fifteen dollars over planning it straight rate and that’s

26:29

allowing and that’s by doing nothing different other than doing a little bit of work and setting yourself up ahead of time and planning the monitor the

26:36

potential in this field was for just over seventeen dollars an acre profit had we had our crystal ball and were

26:42

able to hit the perfect population you know for that growing season with the weather we had the block the graphs are

26:50

on the bottom right show what the ideal target rates were and the variable rate

26:55

potential revenue that we could have made so when we think about that set of graphs that we just want reviewed you

27:03

can see here that the data is telling us that four zones probably weren’t ideal

27:08

three zones would have been enough and that we are correct that 150,000 seed

27:14

breaker average seeding rate you know reducing each of those zones down by twenty five thousand seats breaker would

27:21

have made us more money and would have made us more profitable at at the end of the season both agronomically and and so

27:34

when we look at this farm customer across his entire operation 1,100 acres

27:40

were done with seeding scripts in this year seven dollars and 27 cents was the

27:48

average of the each in every field with an eight thousand dollar net profit to

27:54

the customers bottom line by literally doing nothing different in with his in field operations it takes

28:02

a little bit extra time now to get your script set up put it in your monitors created properly and then we get you

28:11

know to the field we plant like we’ve always done from one side to the other there’s no adjusting equipment there’s

28:16

no changing seeding rates in your within the monitor it’s just plant and finish

28:22

move on to the next one follow it up with the combine at the end of the season harvest as always and then

28:28

submit the data for analysis it’s a real quick and easy way to get some real good analysis and some real good results

28:34

without a lot of time taken in the field and you can see by this set of

28:40

information that it’s we don’t always get it right either our scripts are wrong based on variety performance or

28:47

the zones aren’t quite accurate enough and we need to do a little bit more digging in certain fields you know

28:53

whatever the reason is you can see that you know in this case there’s 1 2 3 4 5 6 7 8 9 10 or 11 negatives there but at

29:00

the end of the day the average is positive and it does show a fairly decent return into the faroe great scrap

29:06

process thanks Mike and here is another

29:16

example of the planning script to harvest for an edible bean field this

29:22

field zones are created based on normalized yields this customer also created these zones for soil sampling

29:28

and now they’re using the same zones for planting and their fungicide applications barrel rate planning and

29:35

fungicide applications you can see from the script to the planting as applied

29:42

the grower hit the targets pretty well and then when you look at the harvest map on the right how close the yield

29:48

zones correlate with the zones created from the normalized yield the prescription is started starting to even

29:55

at the yield in the middle productivity zones and the head lands are still the lowest yielding zone these results are

30:05

from 2019 and based on the season we had around here what spring Jody summer the

30:11

planning it could have been reduced to attained a heart higher ROI yeah that’s great Carla

30:20

as you can see by this graph you know the first and most obvious thing that jumps off the page to us here is we

30:27

should have planted less than every zone the trend is up and to the left meaning more profitable at the lower seeding

30:34

rates now 2019 was in a unique year and maybe we don’t want to put all our eggs

30:39

in one basket and take this approach across the entire operation next year but it is a good case of learning and a

30:46

good thing to see if we see the trend repeat we have done lots of work in edible beans over the last five to ten

30:52

years and we do see the trend of reducing seeding cost being more profitable but the trick is now to

30:58

identify what is the optimum seeding rate in those zones in your field and how do we get to do that and then make

31:05

sure we are hitting the so you can see here this customers average seeding rate

31:11

was about 102 to 103 thousand seats breaker you can see the two higher

31:16

yielding earth sorry two lower yielding areas with the higher seeding rates actually cost a little bit of money in

31:22

this script the red line definitely was a loss the script heard him he would have been better planning at that lower

31:28

seeding rate the yellow line also was a

31:34

bit of a loss not much luckily those two areas in the field were small and and

31:40

because the most of the field was in the higher yielding area the script was still profitable but you can see how the

31:47

green line made money and could have made a little bit more had he gotten further left and the blue line

31:52

definitely made some money and arguably he’s probably getting close to that low-end number you can see how the

31:59

bottom of that curve starts to dip down a little bit in the shaded area so we’re getting close to finding out where that

32:05

optimum level is there’s what we need to start being careful and watch that as your start to come here are the results

32:14

again that with the deliverable to the customer at the end as I said most of the zones in this field where the the

32:21

green and the light yellow the high yield environment as you can see by the map there and so that made the script quite

32:27

profitable and he was able to make thirty four dollars an acre with this very great edible bean seeding script

32:34

animal beans do respond very well the very populations and we can see we see

32:40

great results as we move forward again if we look at that map on the bottom

32:47

right with the ideal target rate that shows us the where the top of each curve

32:56

was and and what rate would have brought the most profit based on the information

33:01

on the graph so to calculate that ideal target rate we look at those curves that

33:08

we see in the graph on the top and we see where the line is highest what the seating area would have been to bring

33:14

the most return to the customer in each zone and we extrapolate that out across the original prescription zones to give a

33:22

map showing what the ideal seating rate would have been based on the information

33:27

received from from the analysis so when

33:34

we look at a typical analysis of the full or fields that a customer did with

33:41

edible beans in in this past growing season again we can see the average profit across the firm from from the

33:49

seeding scripts that were created in this past season we have roughly three

33:56

wins one loss you can see the analysis there on the bottom the 288 acres with

34:02

the 618 average profit with just under eighteen hundred dollars net profit of the customer doing you know using the

34:10

data to his advantage and using some information to make some better

34:15

decisions moving into the 2020 season

34:22

thanks Mike and to go along with those optimal target rates and the best ROI

34:29

other very fair block insights can look at the different varieties in the fields

34:34

this is an example from a seed company where they’re trying to find how each of their varieties perform in

34:41

different production zones which variety yielded the best but also looking at the

34:47

optimal seating rate of each one first graph is a box plot of how the varieties

34:53

yielded by productions on the bottom table breaks down each variety and how

34:59

it yielded in each zone and what the optimal rate was bearer box can also tell you what the yield was of the

35:05

optimal population for that year because it was tested there are many more

35:12

examples of insights that checkbox can provide but these are just some of the more popular examples for planting

35:19

validation and hopefully we’ll have another webinar that just goes a little

35:24

more in depth on the on the analysis piece in the future here so remember the

35:34

four steps from the beginning identify the problem and use existing technology

35:40

to improve it measure the differences if you can’t measure it you can’t improve it we have the ability to measure every

35:48

pass of the fields manage and validate your applications feel specific data

35:55

appeared with strong analytics provides the Sola answers and a proof we need to

36:00

remove some of that emotion prescriptions with check blocks help verify the applications ROI and to

36:07

determine the appropriate rate prescriptions can also help organizations and growers be more for

36:13

our compliant so talking to your agronomist today to see what data you

36:19

need to start collecting you can provide measurable measurable results to your firm thank you and we’ll open up for

36:27

questions hey Carla thank you and Carla actually if you could just keep

36:33

presenting and then I will ask you to jump to specific slides if we get there I’m gonna work through the Q&A session

36:41

here as you guys listen to Carla and Mike talk through we said we’re gonna

36:47

talk about how to set a planning script for your field we talked about the data layers that we use

36:53

and that we recommend that you use if you have your own methods for setting those plenty of scripts then we talked

36:58

about how several ways to get planning script are Oh eyes I’m sorry get

37:05

insights into your plainer scripts and then we talked about some ry+ and actually had a couple negative in there you know it doesn’t always work

37:10

and mother nature is sometimes fickle so we do our best to minimize that we’ve

37:19

got several questions and we’re gonna go through them right now I’ve got three questions in the chat section and I’m

37:24

gonna clear the questions in the chat section first and if you have questions going forward if you could try to get

37:30

them in the Q&A session that will absolutely get over there work through those so Mike and Carla you just

37:37

determine who’s gonna answer these first question is in the chat section do we

37:43

think that the yield map has good accuracy for building our variable rate

37:48

planting scripts again how do we do we think the yield map is it has good

37:54

enough accuracy to build a planning script for next year yeah sure that is a

38:02

yes and no as the answer to that question and I would say that depends on the yield map that you or the or animist

38:12

has chosen to use you’ll get a Ken skew information and provide false things at

38:22

times so you know the more knowledge we have of the field the more information

38:28

we have telling us the stability of a zone the better we have yield is the most

38:35

important data layer and making that decision but it doesn’t always need to

38:41

be the only one when we start using multiple years worth of yield we start to see the trends really unearth

38:47

themselves when we start adding in elevation soil type and some other types

38:53

of zone layers like that then it really becomes clear and we give it a very inaccurate decision crops like soybeans

38:59

where you’re high yielding areas that have get affected by disease like white mold or something that can be

39:05

detrimental to or is a perfect example of how even that it can be skewed and and maybe make the

39:11

results not quite accurate when I’m looking forward but knowing that and

39:17

using some corn yield maps and some elevation data and some other things like that really help to clear those

39:22

issues up so one year’s worth of yield if it’s the right yield and the customer

39:28

agrees with it and the agronomist understands that it did have everything going for it can be used but ultimately

39:35

yes be careful and two or three more the more years worth the better obviously

39:40

that’s where we get normalized you’ll map like this showing us the trends over time and the ability to start making

39:46

predictions on how that fields going to perform thanks Mike

39:52

I’ve got two more questions on the chat section and they they generally all deal with setting that yield rate so I’m

39:59

going to ask both of these questions and then Mike and Carl if you could broadly talk about your response here kind of

40:05

incorporate your answers to both of these the next question is well the next

40:10

two questions are how do you set the ideal rate so how like how do you get

40:18

that number from your recommendations and then right in line with that is how

40:23

do you determine the range of those zones so for example the map you have up

40:29

here you have a seeding rate of twenty thousand thirty one thousand thirty-four thousand thirty eight thousand what

40:35

methods did you – did you guys use – number one set that rate and number two what a recommendations are for creating

40:43

the variation in zone at very rate variation in rates sure

40:49

so that is determined usually by specific knowledge within the area if we

40:56

have seen representatives that know how the varieties perform and population

41:03

range it typically performs best in that’s very very useful information out of the gate if we’re in working with a

41:11

new customer that does not have a lot of data or is unsure usually we use their

41:16

average seeding rate as a place to start because that’s usually what’s worked best for them in the past and then we

41:22

can go up and down from there and we use the data learned from the analysis to

41:27

tweak educate ourselves and the grower and and build stronger decisions as we

41:35

move forward how do we know how far the spread should be in a seeding script

41:42

basically comes with you know the experience of the ground and looking at

41:47

the amount of variability present within the field if your yield monitor is consistently only swinging you know a

41:54

very small percentage from one side of the field to the other then there isn’t the need to put four or more zones in

42:01

that field and there isn’t the need to put you know four or five different seeding rates in that field if the

42:08

fields fairly flat and even then two or three seeding rates is is probably ideal but if you get a field like this one on

42:15

the screen where you’ve got yield swings from a hundred to three hundred bushels per acre of corn and you know there’s

42:20

anything everything from crated clay to gravel across the firm then yes you know

42:27

experimenting with that seed and pushing the envelope a little bit really does

42:33

begin to pay and really does show some some advantages out of the end so it’s a

42:39

little bit of learning curve in year one and two but once you start to understand the process and and how the populations

42:46

can affect the end yield then you can start to hone in and make better decisions across the entire operation

42:53

and other operations within the same area now thanks Mike we have now moving

43:01

over to the QA session we have at least seven more questions here we’ve got about 15 more minutes on the webinar so

43:06

we’re going to do our absolute best to get through all these questions if you have more questions by all means put

43:12

them in there and if we can’t get you in the remaining 15 minutes we’ll send you an email response on our our answers for

43:18

that so the first question in the Q&A section is this this individual has seen

43:24

research that indicates that with soybeans and wheat that 20 to 25%

43:30

seeding rate variation is required to see significant yield changes what

43:35

are your thoughts about that you are you saying do you are you seeing that also as you said the rates yeah I think

43:44

that’s I mean I wouldn’t disagree with that at all I think that will tend to change based

43:50

on the different areas of the world that the prescriptions are planted in Carla if you go to the soybean script there

44:00

you’ll see that you know if we look at the minimum seeding rate there of a hundred and forty five thousand seeds

44:07

per acre if we add forty percent to that number I think it comes out to about two hundred

44:12

and three thousand so you know in that script there we’re actually changing seeding rate by 40% so yeah I think I

44:20

don’t think you need to do 20% with every jump but I think you want to

44:26

probably see you know a decent change in an overall seeding rate to see a

44:31

response from from one side of the field to the other and again the amount that we push that rate change and the number

44:40

of rate changes or zones in a field defi definitely needs to depend on you know

44:45

the variability that you’re seeing in that field and and if ultimately if you’re seeing a response from from that

44:52

from the change itself now thanks Mike

44:58

the next question is a little bit longer but if try to bear with me as I as I asked it and then simply address the

45:04

question is in soybeans the low yielding areas are likely to be in those areas of

45:10

poor soil quality so so therefore the questionnaire says you probably should

45:16

plant a higher density of plants in those areas and so now give the crux of the question how are those plants in

45:22

terms how are those plants in terms of similarity across the rest of the field

45:29

affecting you know so is the issue normally poor soil masques higher

45:34

seeding rate or what are your thoughts about that well very good question and

45:42

yes that is something that we look at and try to watch and I think that is the main

45:49

reason for continuing this process on as we go and learn and as we try to fix and

45:54

change fields so you hit the nail right on the head it is those poor soil quality areas that

46:02

do require the higher seeding rates to one get proper emergence two to promote

46:11

growth and in some competition there in the road to get the beam to grow taller faster shade the ground sooner to help

46:18

combat weed pressures so on and so forth just typically those lower areas don’t

46:24

promote a thick vegetative crop in soybeans or edible beans so increasing populations helps us with that and helps

46:31

to get more pods or acre in general and as you say vice versa that low rich high

46:39

yielding ground is naturally very vegetative the crop grows rank and

46:45

healthy higher populations usually cause lodging increase in disease and things

46:51

like that so that’s where the variable population can help with disease pressure in those areas and help with

46:58

you know weed weed management we pressures in the lower lower yielding areas so you know as we begin to work on

47:07

a field holistically and we start improving soil quality and those who are performing areas if we can if it’s

47:13

something we can manage sometimes it’s not then you know the scripts may potentially change over time as we begin

47:20

to increase yield in those areas then we can start ratcheting back seeding rate and and start making adjustment as far

47:26

as crop quality and things like that go and staging really haven’t seen a big

47:31

difference on you know harvest ability or staging differences in the crop

47:37

usually those tougher areas are the ones that die down or mature faster anyways

47:43

so a thicker feeding rate isn’t usually an issue if anything we see probably

47:48

better harvest ability by reducing the seeding rate in the better areas to

47:54

reduce lodging and reduce the amount of disease making quality go up

48:00

and in the harvest ability easier and better so definitely a great question

48:07

and there’s a lot going on in that question and a lot of other things to measure seeding rate alone is not gonna

48:12

fix the problem it’s more of a way to manage the current problem and and work through it to identify some other

48:18

economic issues that you want to focus on on the firm and tackle to get things

48:23

moving along better it’s so thanks Mike leading right into that then management

48:31

a lot of variabilities how do we if if we combine a variable rate seeding along

48:37

with fertilizer along with fungicide scripts in one field how do we how do we how do we isolate the response for we

48:44

are seeding yeah great question and something that we’re working at to do of

48:50

you know the multi variance analysis and things like that across across different scripts and the short answer is very

48:57

difficult so when we’re talking about very fertilizers and things like that we

49:05

recommend that the customer use the same or very very similar zones to that of

49:11

the planning script and begin the fertilize you know based on soil levels and crop removal levels across the field

49:17

so that most of the entire zone being treated is treated with a very similar

49:24

rate of fertilizer fertilizer itself I know is pretty much proven you know we know crop removal rates we know how we

49:31

need to build the soil so on and so forth we don’t typically do blocks on large-scale fertilizer like P and K and

49:37

things like that we can it just so it was a difficult thing to build and it takes time you

49:46

know five to ten years to fix major issues depending on on how bad they are so you know a block in one year might

49:53

show you something but ultimately not not everything but when we start looking

50:00

at that fungicide nitrogen seeding scripts and things like that then yes a

50:06

small field with lots of zones like some of these we’ve shown it becomes very difficult and our recommendation would

50:12

be just do one thing time learn what works one field at a time and once you’ve proven it to

50:17

yourself and know the response then you can start doubling and and adding multiple approaches to a single field if

50:23

you’re lucky enough to have large acres 100 acre fields plus where the

50:28

variability is large enough that you can put enough blocks in to do two different treatments at the same time then

50:34

wonderful I mean those are fun fields to work with and we enjoy that but we need to make sure that we do not overlap a

50:41

fungicide script block with a seeding script block and we’re able to dissect

50:48

the data at the end of the season properly so that we can analyze both script individually and give you the

50:54

results in total but that is a field by field specific situation and needs to be

51:01

treated that I had a one on one level of that but great question yes you know when we start to manage multiple things

51:07

at a time it can get cloudy if the proper steps are taken

51:14

yeah thanks Mike so right in line with that you may have already answered that but this question is is these these

51:21

examples that you used here were these isolated examples or was there other

51:27

variables one in there and they specifically asked was a very bright fertilizer scripts on these fields that we use an examples or were these

51:34

isolated fields so the field on the screen now know there has not been

51:39

varying fertilizer done with this customer yet although he is seeing enough variability that that is his next

51:45

step and he’s working towards that very quickly because he’s identified there is a lot of variability on the firm’s and he

51:51

wants us are managing it differently the error will be the first edible bean example we showed this field here this

52:00

customer has been doing actually began and started with soil sampling and has

52:06

variable rated the fertilizer on this farm for many years probably 10 plus and

52:13

these zones that we use for this planning script are actually the same soil soil zones that they created you

52:20

know with their agronomist using normalize yield and they’re the same zones that they use for der berating the

52:27

fertile so lots of data with this customer lots of information going on the firm’s and

52:32

you can see here by the stability of the zones you’re in you’re out and the way the field behaves that but they’re

52:38

getting it dialed in very well and you know the results are quite positive for

52:43

this operation yeah next question can

52:51

can this technology can this methodology or way of thinking work on silage can we

52:56

verify corn silage without a yield

53:02

monitor it becomes very difficult that’s the piece we use to you know do the

53:10

ultimate validation and then get us the hard numbers to to prove success or not at the end of the year but I’m not gonna

53:17

say it’s impossible if you’re a customer that has a harvest lab or some sort of a

53:24

yield monitor system on the silage machine that becomes a little bit easier

53:29

I mean we’re now starting to get some yield data and it’s potential that we could we could have some success there

53:35

but without that hard number it’s it is a challenge I mean the concept would

53:40

work absolutely there’s no reason why silage wouldn’t benefit from it as well but to get that ROI it becomes difficult

53:47

there is potential to possibly use an end DVI image and extrapolate some yield

53:54

values out especially if there’s a part of the field left that is combined that we can do to validate and I guess

54:04

correlate the NDVI image back to a yield and you could extrapolate but like I

54:10

said it becomes very difficult and I would say yield is is probably necessary

54:15

to guarantee good results out of the gate

54:24

thanks Mike how do we determine the

54:30

number of check blocks we use so our

54:36

rule of thumb is the more the better without sacrificing the integrity of the script we like to try to get at least

54:43

five blocks of each seeding rate higher and lower in each zone sometimes the

54:51

fields just don’t allow it I mean the picture carla has here on the on screen now is perfect I mean you can see we

54:57

definitely have more than five red and yellow seeding blocks in that orange

55:02

zone for sure in that field you know we’re gonna get some lots of data lots of stability but when we started to get

55:09

into those green headlands area I think there’s still four or five you know but it gets tougher to put the blocks in and

55:17

get some that out of it so and then if you look at that field to the north it’s such a small field it’s hard to get a

55:23

lot of a lot of data out of it so depending you know equipment size

55:29

changes how big our blocks are obviously and the amount of variability within a

55:34

field and field size are all things that that start to determine that but for you

55:40

know good statistical analysis we want as many data points as possible and we want to try to get as many blocks

55:47

in as possible without you know without ruining the script and without creating something that the planter can’t

55:52

physically plant ie rate changes happening so fast that the controller and the monitor can’t can’t adjust fast

55:59

enough and and then creating frustration for the for the customer and the operator in the field that’s one thing I

56:05

want to add to that to Mike is that we can adjust the blocks to like there is a difference in hitting your target rates

56:11

with hydraulic and electric drives so we can adjust the blocks to make them a

56:17

little longer to allow for that adjustment just so you have a better opportunity to hit those target reads so

56:23

we can work with the grower to adjust the blocks to work with their their equipment too so so right in line with

56:30

that then the next question is is how do we validate the planting the planting

56:36

rates are we validating in using the as-applied a later or or do we

56:41

ask the that they are their grandmas ground truth what planet or combination of both yes yeah I mean a ground truth

56:51

is always wonderful it’s not needed for the analysis we do but I think it’s a great great step for the agronomist to

56:58

do with the grower to ensure satisfaction of the script and unfettered understand the field

57:04

conditions and make sure they are seeing what they expected across the field but

57:09

to do the analysis yes is that as applied data compared to the yield map

57:14

at the end of the year that’s allowing us to do the analysis we want the as-applied data so that we can see

57:20

exactly what happened in the field with the planter was description off its

57:25

places was there some straight strips done from one end of the field to the other did the season did they plant

57:32

earlier did they plant late and that they use the script multiplier in the cab and bump seeding rates up or down you know whatever potentially has the

57:40

ability to change in season we want measures so that as applied map gives us that detail and allows us to dissect

57:46

what’s happening it also allows us to see more data points in the field as

57:52

that planter ramps up and ramps down it actually begins to give us you know other seeding rates and other things to

57:59

look at and see how the yield performed you know when we dissect it really

58:05

intense level yeah and then and then right in line with that is if we have a

58:11

late planting season so we got we did all the work over the winter and then we have a late season are we able to adjust

58:18

those scripts and those planting rates with the ground mr. rower yes absolutely you know we prefer that the grower and

58:25

the ground must work with us and tell us the way that our analysis tool works I

58:31

mean the analysis will work and you will get results back beautifully but when we

58:37

look at those vertical lines we were showing on the graph Colonel if you can go to one of those examples

58:42

I’d say the soybean chart or soybean graph

58:49

so you know if we’re looking for the average seating rate to be 175,000 and

58:54

we have those target rate dots on the of the page of each individual target obviously if you use the script

59:01

multiplier in the cab that changes the results and the way the computer does the analysis at the end of the season

59:07

will will will throw it off and give some skewed numbers so knowing how you

59:13

change that the script and whether you increased or decreased it allows us to tweak that before we do the analysis to

59:20

give you the most accurate results nonetheless you will still get a set of curves and you will still see the trends

59:25

and you know it will still give you some answers but yeah but yes you definitely

59:31

can be changed and modified as the season changes that’s a very important yeah great and we’ve we’ve still got

59:38

three questions and we’re gonna do our best to get through these I hopefully we don’t get kicked off here next question is do we have any data for best

59:47

management practices for other crops such as canola’s or cereals have we

59:53

applied this methodology to things other than you know beans and corn a little

1:00:00

bit yes corn soybeans and edible beans are the major three we’ve done that’s where most of our data lies today we’d

1:00:07

love to start working in the other crops to build a database and help other customers learn the process would be

1:00:13

identical in wheat and cereals you know we tend to see the similar trend where

1:00:19

you want to increase seeding rates in those poor who are growing environments

1:00:25

typically because you know we want to promote tillering and promote more heads per acre and those low over you know

1:00:33

those that lower unproductive soils and then obviously in that really high

1:00:38

producing areas where we get tons of tillering naturally lots of heads breaker you know I think that’s the oh

1:00:45

that’s the areas where we want to you know look at potentially decreasing seeding rates and then you know

1:00:50

ultimately the Knights of your management program on top of that becomes critical to ensure that we are

1:00:55

feeding the crop properly and timely and to promote that tillering and get the

1:01:01

get the proper amount of plants and heads breaker we need we’ve done a small amount of work in the cereal market and

1:01:07

and you know those are the trends we’re starting to see out of the gate the canola piece and some of those other

1:01:12

crops we have not as of yet but definitely would be interested in working with customers on that and and

1:01:18

then learning and identifying the key factors as we move out next question is

1:01:26

uh is the profit numbers that we showed so the examples that we showed and then we had a profit number in there do those

1:01:33

numbers include fixed costs and variable costs like like what is that number though where’s that solar based on

1:01:38

reaction increase in decreasing seating yeah that’s just the reaction to seed so

1:01:44

those numbers of nonprofit on the charts are just your profit breaker from this

1:01:49

heating operation alone and these numbers that we’re seeing there are just the increase in profit or decrease in

1:01:57

profit with the seed cost and the cost of the prescription taken off so all

1:02:03

other costs in the operation fertilizer chemical land rent all those other fixed costs are not added in the calculation

1:02:10

simply because there’s I mean that would be next to impossible there’s too much information to get and every field and

1:02:17

every operation is so drastically different as hard so this is just taking into consideration the price of the seed

1:02:24

the cost of the prescription and the net impact that prescription has on on that

1:02:32

seeding operation and then and then landing right ends of profitability this

1:02:40

next question is lower seeding rates may be profitable in a year but can you

1:02:46

balance does that balance out with the good agronomy is it what what is lower seeding rate overcome by around me and

1:02:52

this this questionnaire is specifically thinking about does a lower seeding rate

1:02:58

effect weed competition and maturity like what’s your thoughts on that interaction sure absolutely and I think

1:03:05

good agronomy is key to this whole process I mean without good agronomy no no this

1:03:11

works you know we want to change seeding rate based on the economic practices we know

1:03:16

on the firm we want to make sure you know what we do on a sandy firm seating

1:03:22

wise is very different than we do on a clay firm so why are we not treating a

1:03:27

field specific it’s specifically based on those same soil types the sandy area

1:03:33

is on the firm yet seeding rate and the clay area is on a firm yet seeding rate

1:03:38

B so the tree I thought processed sand and the goal is to identify the zones

1:03:45

properly so we are managing those soil types accordingly and we are applying

1:03:51

that good agronomy to each of those zones properly so that we get the best result and we know when we are

1:03:57

economically correct we are usually most economically correct to not every time but you know I would

1:04:04

say 99% of the time in most cases when we start looking at weed pressures and

1:04:09

things like that you know usually it’s it’s a non-issue we mean we’re not cutting seed back enough that’s gonna

1:04:16

affect you know sunlight and you know the shading of the ground and competition if anything you know I think

1:04:24

we probably get an increased benefit in weed control and shading of the ground

1:04:30

by you know increasing and getting canopy closure earlier on those tougher

1:04:35

areas and I know you know preserve moisture and some of those other good benefits that happen so we try to adjust

1:04:42

our seeding rates accordingly based on the agronomy the we know I wanna farm and ultimately based on what these

1:04:50

curves are telling us and when what the results show us over time excellent and

1:04:57

and to close out our questions and we did a little bit long but as we see

1:05:03

probably three-quarters the people are still engaged so Mike you’re given market colors given good responses this

1:05:09

last question may be a philosophical question I’m not sure but I’m assuming they don’t mean threw money at it so if

1:05:15

you have good ground that has a tendency to drown out and I mean about you know

1:05:20

throw money at it all right put in put in some tiles and I’m assuming they’re not saying let’s not go that way

1:05:25

those areas are typically red and your you’ll monitor because they drown out but they’re actually really

1:05:31

good ground so what’s your recommendation for set in the seating right there great ground that drowns out

1:05:37

on a higher-than-average sure so I mean that starts to become more of a customer

1:05:45

specific and zone specific goal in something you know when we start looking at that normalized yield map those start

1:05:53

to become our unstable areas you know those those areas of unstable yield where the yield like a bugger on and on

1:05:59

a great year and they drowned out or on a wet year or they burn off and dry up

1:06:05

completely on a drought year thinking of an old type situation you know those unstable zones become very challenging

1:06:12

to write scripts for not impossible and and and not I mean it’s definitely

1:06:18

something we need to manage but understanding that instability of those

1:06:23

zones and why it occurs really starts to drive you know the success of your

1:06:29

scripts and how you make them profitable so a very good point you know I would

1:06:35

start to ask questions of the customer and find out what their comfort level is in those zones and maybe just specify

1:06:42

those those certain areas that drowned out differently you know ultimately it

1:06:48

is the best yielding area on the firm and if we don’t get that’s a situation where it drowns out you’re gonna want

1:06:54

your seeding rate to get the best bang for your dollar on the flip side when it does drowned out I want the seed there

1:06:59

because it’s just an added expense so maybe in those unstable areas or there is it you know her like that you just

1:07:06

move back to that average seeding rate or that or that middle zone so that you’re not putting yourself at risk you

1:07:14

know in both directions it’s the best bang for your dollar there’s enough seed

1:07:19

there to give you a decent yield when when you get it and you’re not breaking the bank with the ton of seed on the

1:07:26

years of floods out so you know different areas of the field and those are things where the one-on-one approach

1:07:31

and

1:07:42

yeah great appreciate the response there Mike I would like to we have been able to get

1:07:48

through all the questions and and we greatly appreciate everybody who who type in your questions and asked I’d

1:07:55

like to think Mike and Carla for leading us through this webinar today and most

1:08:00

definitely would like to thank all of the attendees who joined us you are why

1:08:07

we’re here and our whole goal for these webinars is to to help increase adoption rate uh precision AG tools and

1:08:13

technology and start to understand how to use data to get a positive ROI I mean that was the crux of this webinar today

1:08:20

was how to get a positive ROI for your planning script so again we appreciate

1:08:26

everybody joining us we will be sending out a recording of this webinar to

1:08:31

everybody who joined and you feel free to share that with your your peers or whatever if you think this is valuable

1:08:37

and if you’d like to have more webinars like this I mean we are all about

1:08:43

increasing the adoption rate of precision AG tools then please email us and tell us what your what your

1:08:49

preferred topic may be and if it’s something we can do we will absolutely queue that up for a webinar we again

1:08:58

appreciate it and with that we’re gonna in the webinar and look forward to kissing everybody the next time