Video Transcript

0:00

we think we got our audio sorted out folks Scott has handed the presentation

0:06

over to myself it’s Aaron Breimer here speaking he was just giving us that giving everyone an introduction to the

0:13

company devran has two main focuses one is around data collection so that’s the

0:20

soil sampling imagery collection utilizing drones and then the other half

0:25

of our business is heavy on data insights and that is the group that that

0:31

I manage and work with so today’s presentation is going to be around some

0:36

of those data insights that we have created over the last couple years so god had posted the poll questions we

0:45

like to share some of the poll questions just for everyone to have an idea who’s all involved so at this point it looks

0:52

like the vast majority of you heard about this webinar through the email

0:57

campaign five percent of our folks today

1:03

are growers farmers 36 percent are independent agronomists 26 percent are

1:10

in the AG retail space and 38 percent are from the AG tech world and the

1:21

question with regards to what is your current level of experience with variable rate nitrogen 33% of you have

1:28

indicated none 28% have experimented with some with it somewhat 18% are

1:34

occasional users and 21% have identified themselves as extensive users or that

1:42

you have extensive experience with it so this should be a fun group to share with

1:47

what interests you most about variable rate nitrogen 26% so just over a quarter

1:53

or indicate it’s all about higher crop yields or that’s the most interesting

1:58

about 38 percent forty percent now is around reducing costs and 33 percent is

2:06

around the improving the environment

2:13

– footprint see question number five and for those of you waiting for my

2:19

presentation to pop back up just as soon as I get the polls then we will present

2:25

my screen what is your limiting ability to utilize

2:30

variable rate nitrogen so multiple choice here about a quarter is that they

2:36

don’t have that you don’t have the required equipment about a third is confidence on the return on investment

2:43

that’s gonna be a lot of fun to share with you guys today some of the data that we’ve been analyzed and over the

2:48

last five to six years about seven percent I it’s a time piece tell me

2:56

about it we all get super busy so maybe we can find ways to make your life a little bit easier but a quarter is a

3:03

knowledge piece and and another quarter

3:08

is around just needing more customers to participate and our final question what

3:15

is your preferred data layer for setting your nitrogen rate and zones about 20%

3:22

is experienced 30% is imagery 37% is

3:27

previous yield maps 30% is pre-established management zones and it

3:34

looks like we got a couple people that are wondering what we’re talking about with data layers so hopefully we get a

3:41

chance to present that and now I’m going to flip over to you guys being able to

3:48

see my screen

4:00

all right so uh everybody able to see my

4:06

screen it is the five pillars of success so all good webinars have a little bit of a sales pitch so we’ll get this out

4:13

of the way superfast and get into the meat and potatoes of the presentation so

4:19

the five pillars that we look at when we’re talking about all things precision egg the first my screens gonna work is

4:31

all-around simplicity if it’s not easy people are not going to use it I grew up

4:39

on a farm my parents are still actively cash crop farming and dad is let’s say

4:46

bad seventy-three years old now he does very very planting very bright nitrogen auto steer and collect steel beta if we

4:53

didn’t make it easy for him he would not be doing it so its simplicity is very

4:59

important those of you who indicated a time crunch we all know that if things are not working the way they need to be

5:04

when you start you’re gonna turn it off next one I truly truly believe that

5:12

every farm is unique not only is every firm unique every field is unique and for those of you who indicated it’s all

5:18

about management zones I would agree even within the field different things are going to be different so

5:25

understanding that the uniqueness is a critical piece Devron we’re all about

5:34

innovating we’re constantly asking for feedback we want to know what challenges you’re facing we want to understand what

5:41

your objections are to what’s being brought to the market so that way we can find improvements and solutions for you

5:48

we are not interested in sin still one of the really cool things about our webinar series is that we like to share

5:55

what we’re working on so everybody else can have an idea of what what it looks like and give us that feedback so we can

6:02

keep moving we don’t have all the solutions but we have a strong desire to

6:07

find the solutions here’s a big piece were talking about the return on

6:14

investment and feeling confident when it comes to variable rate to nitrogen we talk about validation did it actually do

6:21

what it was supposed to do and this can be a challenge especially when every field is different every firm is

6:26

different time is a challenge what is a system to be able to validate and

6:33

understand what is return on investment and then the final one is around this

6:40

piece called inclusive some people call it a collaborative relationship farmers

6:46

have a huge network of people that they can rely on okay they have their egg

6:51

retailers they have their seed partners they have their equipment dealers there’s extension folks and for us

6:58

inclusive that collaboration is how do we all truly work together that is

7:04

easier said than done everyone likes to talk about collaboration it has been our

7:09

experience that is a challenge requires a lot of trust and it requires a

7:15

confidence to be able to work together we’ve got an offer at the end of the presentation around how we are going to

7:22

get give you guys a chance to test us out on that collaboration so something

7:27

to look forward to all right presentation overview that’s the sales stuff let’s get into the good stuff as I

7:34

mentioned I grew up on a farm I’ve got my bachelor science agriculture degree and let’s see ten years in a grete ale

7:43

followed by nine years into precision AG consulting space and as I mentioned I

7:50

now am the general manager of our data insights group the data insights group we run under the brand called Veritas so

7:57

when you see that on the screen that is it’s the connection so Devron is the company Veritas is the data insights

8:04

group within there we’re going to talk briefly around the nitrogen overview

8:09

some of the opportunities some of the challenges you’d have spend a nice bit of time

8:15

around the promises and technology this presentation is around the facts and fables of variable right nitrogen and

8:24

a lot of the facts and fables are going to live in their promises and technology and technology that we see definitely

8:32

going to go over a bunch of testing and results that we’ve had and how we

8:37

execute that so that way folks are able to get a good input and then finally

8:43

we’re going to summarize the presentation so any good stuff all right nitrogen I call it the sexy

8:51

nutrient and here’s why 57% of all fertilizers are applied this

8:57

was the most recent numbers that I can get indicated at 57% of all fertilizer

9:02

applied in North America was nitrogen based fertilizers you can see 20% is

9:09

phosphorus and 23% is potassium for those of you who promote micronutrients

9:16

looks like those numbers didn’t get lumped in so it’s these big three that are involved let’s face it nitrogen for

9:25

the most part has an annual shelf life and when we mean by the annual shelf

9:31

life is that it’s something that we have to address every year it’s not an in most crops in corn and wheat cotton in

9:39

canola a little bit different when we get into soybeans but it does have that annual shelf life that we have to

9:45

address it year in year out it’s not that you can put extra fertilizer down and that’s going to be around for a

9:52

longer period of time it is almost always one of the top three costs that a farmer has to deal with the deficiency

10:00

is visible this is a nitrogen response trial you don’t have to be a very good

10:07

agronomist to be able to pick out where the nitrogen deficiency is and in fact in my experience I have yet to meet a

10:14

farmer who was honest with me that has never done an accidental

10:19

nitrogen trial at some point whether they skipped one pass whether they ran out as soon whether it was that weird

10:26

corner that they couldn’t get into whatever the reason was at some point a farmer has done an accident to let

10:33

nitrogen trial and we all know that nitrogen pays so there is a and reside pile of

10:40

research every land-grant university that I’m aware of has done extensive research on that nitrogen because it’s

10:47

one of those questions that keeps coming up because let’s face it as I said nitrogen is sexy another piece there is

10:56

huge field variability whether it’s soil type whether it’s management and we’ll get into some of this further into the

11:03

presentation field variability has a huge impact around nitrogen when we talk

11:08

about the validation where I get into a little bit more of this and then the

11:14

other one in this assay showed up in the pool this was a significant concern is around the environmental impact of

11:21

nitrogen fertilizer the University

11:27

professor of mine describes nitrogen as a leaky system so all good certified

11:32

crop advisors and agronomists are very familiar with the nitrogen cycle so I’m

11:37

not going to go over the nitrogen cycle while I am going to talk about our two

11:42

sets of variables and the first set is what we call these controllable variables so this to me your crop type

11:48

if you are growing soybeans you do not need to worry about nitrogen or not very

11:56

much if you’re growing corn or wheat or canola or cotton then you do have to

12:03

worry about it and you do have to be able to manage it corn requires a lot more nitrogen than

12:09

wheat for example the other piece in there our control is the fertilizer

12:14

application so this is comes back to the forest the right time the right plays the right rate and the right source so

12:20

that is something that we are able to control as agronomy or as the agriculture professionals and then the

12:28

final one that I mentioned here is a control of controllable variable as a little bit of a segue to the uncontrollable is irrigation if you have

12:35

the ability to irrigate you can control that to a certain extent most irrigation

12:42

schemes that I have seen there is often some restrictions as to how much can be

12:47

irrigated when it can be rated and pieces like that so it’s not completely control and that’s face there’s a lot of corn

12:54

production on a lot of wheat production that does not have irrigation so hence

13:00

the asterisks on that line and the uncontrollable variables like I said that irrigation is a Segway because

13:05

weather weather is a huge part of nitrogen and making it a leaky system

13:12

the rainfall the patterns of rainfall when it’s coming down temperatures that

13:17

involve a pile of different pieces in there and then the other part is soil

13:24

properties some people could argue that you might be able to modify the chemical properties slightly but that is going to

13:31

be pretty expensive in my experience but then the physical and biological once

13:36

again maybe you can modify it or influence it but you cannot completely

13:42

control it in my experience so if you’re into the whole leaky pipe if you’re not

13:48

a big fan of the nitrogen cycle there it is exactly so you had your nitrogen

13:53

disappearing from different sources if it was a straight full pipe if this air

13:58

buried nitrogen would be easy unfortunately that is not the case technology overview all right here’s a

14:05

good stuff everybody seems to love to talk about imagery indexes this could be

14:11

NDB I something called G NDVI you might hear about red edge I’m going to get

14:18

into the big Sciences behind it here’s what it is it’s using wavelengths reflectance from the plant and it’s

14:25

creating that these different indexes these different ratios if you will so the NDVI which is probably the standard

14:32

for most most of agriculture is taking the near-infrared subtracting the red

14:39

band and then dividing the whole thing by the near-infrared band plus the red

14:45

band and here’s why the majority of plants not all but the majority of plants this is what the

14:53

photosynthesis absorption is so this is how the plant gets its the energy z2 blue light or red light and so when you

15:00

get into a lot of these indexes they’re looking at either that red light or they’re looking

15:06

to a lesser extent that that green light and what’s going on here is so

15:12

near-infrared is to the right of that red curve where it’s disappearing so what the what we’re trying to analyze is

15:20

what is the ratio that the plant is absorbing of that red light so that is

15:26

what a lot of these indexes are doing and a lot of it’s done by what we call multi spectral sensors for some reason

15:33

in the industry we like to use fancy words this is basically a specialized camera that can capture different

15:39

wavelengths of of light that’s literally what we’re talking about when we’re talking sensors it is a

15:46

camera here is the major part that makes NDVI work or not work and that is the

15:55

assumption that nitrogen is your limiting factor it is not always your

16:01

limiting factor and that is the challenge behind this there is a concept

16:07

called hyper spectral imagery and basically to a multispectral camera you might have three four maybe five

16:15

different bands of light and then you can look at that different combinations hyperspectral is this mass of data set

16:23

I’ve seen sensors cameras that can capture up to 256 different segments and

16:30

then you’re getting into all kinds of combinations you’re talking massive statistical analysis on this not saying

16:37

that it will ever have a fit for us but at this point hyperspectral is the realm of the

16:44

researchers like I said sensors that’s it this is your cameras so this can be

16:51

the handheld I’ve seen different handheld ones that you can take a NDVI

16:56

reading you can definitely set up sensors on the drones and a lot of

17:02

people are starting to have crop health maps or NDVI maps from satellite imagery

17:11

just like sensors as cameras everyone likes to talk about algorithms

17:16

algorithms all it is a simple equation well maybe not simple but it’s an equation it would be so much

17:24

easier if we just told and users that’s what it is it’s that your NDVI is this score the equation says you need to put

17:31

this much nitrogen down the challenge with algorithms is they require constant

17:36

ground-truthing testing or a precise dressed nitrate test or a pre-plant

17:43

nitrate test or a post harder stock nitrate test so you need to be taking

17:49

all those different testing to make sure that your algorithm is accurate unless unless you are going to go to the

17:56

assumption that one algorithm is going to work for every farm for every field

18:01

for every management zone I believe that every farm field management zone is

18:08

unique so having one algorithm that’s going to work for everything is a little bit of a challenge from my way of

18:14

thinking and we bet on some of the examples that I will show in my opinion

18:20

if you are going to do variable rate nitrogen you absolutely must be testing

18:25

if you’re not testing you’re setting yourself up to not be able to take full

18:31

advantage of it next piece that I want to talk about is this concept of

18:37

buffering of the soil of nitrogen so it’s literally the ability of the soil

18:42

to provide a stable source of nitrogen available for root uptake so it could be

18:47

soil type so here we have two different soil types and you can see depending on the year where the optimum nitrogen rate

18:55

is two very different soil types and you can see that the curves are different so

19:01

you once again taking into consideration what’s going on with that that soil in

19:07

my opinion it’s influenced by organic matter soil type and a big big piece is management practices talk about soil

19:15

water supply as well but if you look at management so if buffering capacity is

19:21

nutrients into the roots the nutrients can be available but if you mud your corn in you know what I mean by muddy in

19:26

your corn and you got on there just a little bit early or on the heavier part of your firm

19:32

Headlands and caused us and compaction of the roots can’t get out you’re going to have a challenge I’ve got another

19:38

data set this is from a long-term study this is actually 10 years of different

19:44

optimum nitrogen rates exact same site so your soil types of soil all stayed

19:49

the same but weather is that influence ahead so this is this becomes the challenge is trying to figure this part

19:55

out from that study there is a strong

20:01

belief that soil water has started to play a big part so if you go back to why

20:07

Biggs law of the minimum we were talking about soil conditions and other growth factors like the management but then

20:13

you’ve got this this water and nitrogen and how they are influencing each other

20:18

so from that 10-year study rainfall from

20:24

v5 to v12 is showing a very strong correlation to what’s called the maximum

20:32

economic return of the nitrogen so depending on which paper you might want to use optimum nitrogen response rate

20:40

there’s different terminology basically it’s what is the ideal and you can see there’s fairly strong correlation to

20:46

that based on the rainfall each one of those data points is a different burn based on the different year so in every

20:54

case this was the same variety you can see the burn which is the maximum

21:01

economic return of the nitrogen has very little correlation so the closer to 1

21:07

the higher your correlation is so for planting to the v4 very little to no

21:14

correlation you can see in that v5 to be 12 and if you’re wondering one AME why

21:20

is that is the yield that is achieved when you hit the Merc that the maximum

21:25

economic return but very little before that b-52 v12 and then very little after

21:31

that VP that v12 Sueno into that VT and r1 or even later so this is assuming

21:39

about one or two passes of nitrogen here’s the thinking behind

21:45

why this is actually something from Ross bender who is it works for mosaic and he

21:52

is segmenting note where the nitrogen is heading in the plant and you can see right around the v10 stage the corn

22:00

plant just goes absolutely wild for nitrogen stocks up as much as it is a can and so up to that stage we’re trying

22:09

to get if guess is not the right word we’ll try to accurately predict and

22:15

accurately is it in air quotes in this case around what is your ideal nitrogen

22:21

so I’ve indicated that anything past v10 nitrogen becomes critical we are

22:28

attempting to match the side dressing with the potential yield now nitrogen

22:36

moves through mass flow so it requires water so if you don’t have water try to

22:42

get it into the roots as a challenge so waiting to v10 is great because you’re

22:47

gonna have a better idea am I dealing with a 250 bushel corn crop or am i dealing with a hundred and fifty bushel

22:53

corn crop the challenge is is view wait to v10 and you don’t get any rain and you’ve got that nitrogen sitting on the

22:59

surface trying to get it into the roots is next to impossible if you go and you

23:04

put your nitrogen on at b5 you have a better chance of getting that rain to get the moisture get the nitrogen down

23:10

into the roots however you don’t have as much of a window as to the optimum time

23:16

to get nitrogen and I write down one of the things that we see in the industry

23:21

is this concept of wide rot I mentioned my drop there’s a bunch of different systems on on the market

23:27

basically it’s draw piping and nitrogen down into the canopy and the idea being

23:34

that the limited rainfall from the corn plant acts as a funnel and gets the

23:41

nitrogen down right around the the base of the plant the challenge with this is

23:49

most application systems are go putting this on at the six seven miles per hour

23:56

I challenge out any of you to put a proCamera on one of these machines at

24:02

600 miles an hour and watch how those hoses are whipping around they are not

24:08

able to place that nitrogen right by the rope consistently it is going back and forth all over so you need that

24:14

consistent ring this is a study coming out of Aaron Stefano’s who was with an

24:22

egg reliant seed brand he is now with mosaic as well and what he did was he planted three different varieties and he

24:29

did four different nitrogen programs he did no late-season nitrogen he put

24:36

nitrogen down just at the v8 stage he put nitrogen down just at the v12 stage

24:41

and then he did a combination so that is your six tiers are you fixed varieties

24:47

you can see the that really no response difference between v8 and the

24:53

combination waiting too late definitely had an impact this is what we call the

24:59

fixed around so our flex around so this is the corn varieties that can alter the

25:06

number of kernel rows and then the final one is the fixed long and these are

25:12

varieties that are adjust the length of a year based on moisture rainfall

25:19

nutrients pieces like that it’s a great study bid to be able to understand how different hybrids are interacting with

25:25

it once again showing that you have to take all these variables into consideration all right now we’re gonna

25:33

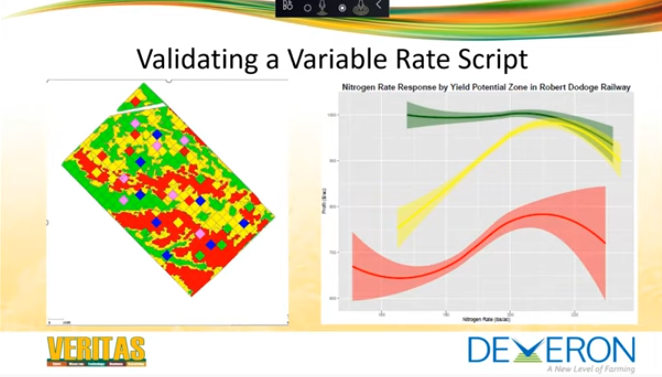

get into how we validate a script this is something that I find very interesting but I’m a little bit of a

25:39

math guy so I’ll do my best to explain how this works what we can do is we create a management zone and then we

25:46

insert randomized check blocks all over it so we can have all kinds of very

25:51

different rates so literally every one of our scripts that we send out the door we turn into a complete randomized block

25:59

design so those of you or statisticians will understand where I’m coming from with that we set it up so it’s super

26:05

simple that nothing extra Hospital you don’t have to be leaving check strips the check blocks are doing all the work

26:11

for you you run the script it said taken care of now when we do the

26:18

analysis we are not using the targa rates which is what these what the

26:24

script is running what we are actually take is we take the actual as applied data so that allows us to have a

26:31

continuous flow of different data points and we split those blocks up so we’re

26:37

getting a lot of data and we use a regression system and we split it out as

26:44

you can see in two different management zones this was one of I thought I had nitrogen figured out about five six

26:50

years ago I wanted to put more nitrogen down where the corn was gonna yield three hundred bushels per acre so that’s

26:57

what I thought I needed to do and that’s what I attempted to do and boy was I wrong what we found was that the best

27:05

response to additional nitrogen was the median productivity and the low productivity zone the high productivity

27:11

zone actually did not need excess nitrogen and one of the thinking’s

27:16

behind why that is the case is because if you think about in a lot of cases

27:23

that high productivity zone has a lot of extra nitrogen around because of organic

27:30

matter I’ll show you what I mean so nitrogen from organic matter if you take a furrow slice which is the top six

27:37

inches of soil works out to on average two million pounds yes I realize

27:43

different fields are gonna be different but on average bear with me two million pounds in the top six inches of an acre

27:50

so if you took it all off and you waited that’s how you come up with that number for every one percent that is organic

27:58

matter from your soil test that is it means twenty thousand pounds in that six

28:04

inches is as organic matter now if you assume 15 percent of organic matter is

28:11

nitrogen and I have seen numbers from 12 and a half to 17 and a half from the research so I used 15% if you want to

28:18

argue one way or the other by all means the concept is stays the same at 15% of

28:24

organic matter so for every 1% of organic matter you have 3000 pounds of nitrogen

28:30

so if for example if you had 3000 or 3%

28:35

organic matter you actually have 9,000 pounds of nitrogen locked up as organic matter going back to the research papers

28:43

once again between two and two and a half percent of all organic matter is

28:48

marelize on any given year yes I recognize that some papers are gonna say

28:53

it’s one percent and I also have papers I will tell me four percent I will tell you it changes depending on the year it

29:00

depends on the soil type once again this is why we’re doing psn t-test preside restraint retest replant nitrate test

29:07

because we’re constantly evolving it but if you were to take that two and two two

29:14

and a half percent and if you had a soil test that had only one and a half percent organic matter i recognize for

29:21

some of you that are on sharp sands that might be a dream to be at that point but at that point you would be looking at

29:27

between 90 and 110 pounds per acre of nitrogen is mineralized that’s assuming

29:35

that the roots can get to it management zones stuff like that management practices all come into

29:40

consideration if you had doubled it so three percent organic matters some of

29:45

you clay guys so it will be able to relate to that so it can be up to 220

29:51

pounds per acre that is marelize on any given year that’s mean it’s going to happen every year and the other piece

29:57

that I want to stress is nitrogen mineralization is a very very dynamic process please do

30:06

not go away from this webinar thinking that if you have three percent organic matter that you don’t have to put any

30:13

nitrogen down that is not what they were saying at all what we’re saying is that

30:18

there’s a lot of nitrogen available there and all depends if it’s actually

30:24

getting into the roots I’m going to use an example this is actually from my father’s firm a couple years ago and are

30:33

based on the experience that I had before the lower productivity zones so

30:39

the red I put more nitrogen down and you can see

30:45

there was a little better response but it dropped off pretty quick the second

30:51

lowest productivity zone that yellow line I’ll shows a continuing declining

30:57

curve not exactly what I was expecting it’s actually and if you look at the

31:03

green and and definitely the blue in the case of the blue curve that’s the best

31:08

ground and I wasn’t getting out of nitrogen on there so my father was not

31:13

super thrilled to see the city’s results and this is why comes back being important to be constantly testing to

31:20

understand if it makes sense with what your rates are going to be now one of

31:29

the things with my father that he absolutely loves to do and those of you were paying attention my dad loves to do

31:36

work with cover crops and I’m not gonna get into cover crops a whole lot we’re gonna have another webinar around cover crops in the near future but is to

31:44

understand the carbon to nitrogen ratio what we have found is that if you had

31:49

are going doing corn on corn or oats and cereal rye as cover crops why would you

31:56

actually end up having to do is you have to invert the the thinking that we had

32:01

originally and that is the corn on corn you’re gonna have a lot of residue on

32:07

the best part of your ground and that extra carbon is going to soak up that extra nitrogen that is being mineralized

32:13

like I said it’s very complicated situation same with oats and cereal right you’ve got to be able to manage

32:19

that same with manure application it’s basically an uncontrolled slow release

32:26

fast release depending on the year release and understanding if are you incorporating it are you experiencing

32:33

compaction how are the roots interacting with that nitrogen tissue testing soil

32:39

testing to understand what’s available in order to be able to make the best recommendations I’m sorry but I really

32:46

disagree with the idea that one algorithm is going to solve all this it can make significant money but you have

32:54

to be thinking about okay what actually makes sense management zones great great idea

33:00

but think about what you actually want to do we’re going on with that management zone another part in cover

33:07

crops is legumes this is a winter wheat field very common in some parts of the

33:12

world to spread red clover seed in the spring and then after the wheat the

33:18

clover grows up and then the fall they terminated and thinking that there’s nitrogen credit you don’t have to be a

33:25

rocket scientist to figure out that there’s huge variability there we’re actually doing a fairly significant

33:31

study we have 21 sites this year where we are actually counting clover plants

33:37

find the fields for NDVI to try to measure the clover and then taking it to

33:43

the following year and doing variable rate nitrogen on there too let’s see what the Maitre D’ responses once we

33:49

have that data will be happy to publish and share with all of you now

33:55

interesting thing that we have already found on that because this was actually started last year so this is our first

34:01

year we’re doing the actual nitrogen is the number of plants that tends to

34:07

correlate very nicely to the clover the

34:13

coverage that we see in the field however the clover coverage tends to

34:20

correlate very nice to the NDVI the conclusion you’d like to draw is that plant counts should correlate NDVI and

34:28

it does not so a big part of this study for us is going to be is it plant counts

34:34

that’s important is it clover stand like clover coverage or is it the health of

34:39

the clover that NDVI that is correlating with India with nitrate levels and then

34:47

also into the yield results so variability huge piece almost done

34:55

something else that we’ve been working with is this concept of green snap so

35:00

we’re able to use a droney imagery to be able to identify and quantify how much

35:07

stop is happening me in a field so this is a you can see the bare ground image

35:12

on my left as well as a imagery index

35:17

all of those tiny little black specks that’s where green snap is happening now

35:23

have you started looking back and forth between those two pictures you’ll see a

35:29

lot of that green snap tends to be coming from that darker a soil type especially down here and the bottom left

35:36

corner there was a lot of green stop there in a lot of cases because of that

35:43

extra nitrogen and here’s what’s going on some of you might be familiar with Mulder’s chart nitrogen has a

35:51

antagonistic approach or impact on both boron and potassium and both boron

35:59

potassium are important in cell wall strength so having extra nitrogen around

36:04

so pumping the extra nitrogen down either pre-planned or a side dress and then also having all

36:12

that extra nitrogen coming being released from that organic matter is leading it to both boron and potassium

36:21

being antagonized and end result is we are seeing more cases of green snap from

36:26

excess nitrogen so it’s another part of that puzzle that we’re looking at crop

36:33

health maps this is actually a weak image so this is what we call red green

36:39

blue this is what you see with your naked eye this was taken last fall this

36:44

was a crop health map coming out of a satellite this spring and as you can see

36:49

there’s an area towards the left that the crop health is not very good and it

36:55

doesn’t seem to correlate very well with that first image so the question is is what’s going on there well based on our

37:02

experience where the crop is not as healthy we need to be putting more nitrogen on that has been our experience

37:08

so that’s what I would would Burnley recommend however talking to the grower

37:14

that area that does not have good crop health it’s not that it doesn’t have

37:21

good crop health the crop is dead what happened is it’s winter kill there was

37:26

snow that melted and then ice and it just killed the wheat so putting extra

37:32

nitrogen on there extra nitrogen is not going to bring back a dead crop so what we actually did was we created a more or

37:38

less an on off script that would turn his sprayer off as he was going across those dead areas so once again just

37:46

assuming crop health and that’s how you’re going to do it probably not ideal

37:52

all right summary very nitrogen has a lot of moving parts I think everybody

37:58

has heard that there is definitely no magic solution there’s huge parts around

38:06

the economics and weather the longer that we can hold off on applying nitrogen and still ensure that the

38:13

nitrogen is going to get down into the roots the better the economic certainty of our recommendations definitely can

38:22

use imagery I love using management zones whether they’re based off historical yield data whether they’re

38:29

based off of imagery absolutely I love it but you need to be looking back at

38:35

what’s going on with the productivity zones here’s an example I think this was

38:41

actually included in the invitation to this webinar I feel that I’ve been working with this is actually on

38:48

management zones based off of three or four years historical yield data now

38:54

it’s three or four years of historical yield data but these management zones

38:59

have been pretty static and on any one year of yield data I can probably come up with something very close to this so

39:06

it’s not a case that you need to wait three or four years just like with that wheat example you can go in there with

39:11

airborne nitrogen in there with just one year of imagery past tests and more

39:19

testing yes you can put in track strips yes you can put in check blocks but you need to be able to analyze that data

39:26

afterwards we are all busy if you’re not comfortable analyzing the data or if you

39:32

want some help we would be to talk to you we do not have to write the scripts if you want to write your

39:38

own scripts and ship them over to us we will be happy to put our validation and a system on there and work with you to

39:44

be able to validate it we don’t have to put our name on on any of your material we’re here to support you so call to

39:52

action on that huge economic opportunities for both the farmers and the industry on this piece let’s face it

40:00

farmers love to say I’m spend money if you add a little extra money to a farmers bottom line they will spend it

40:08

environmental sustainability hey that’s for all of us we need to be doing a better job around nitrogen and here’s

40:16

the thank you for everyone reach out to Devron I think everybody would have

40:21

gotten an email from either Scott or Carla or Josh my colleagues and they

40:27

would be happy to have a chat with you around giving you that validated script

40:36

after this presentation here you’re gonna get another email from them feel free to shoot them back a direct email

40:43

reach out to us through our website we would be happy to make sure you guys were able to take advantage of that also

40:51

if you just want to have a chat with me there’s my contact information I do exist on Twitter I have been known to

40:57

get myself in trouble once in a while on Twitter so I try to behave myself but if

41:03

you do want some entertainment once in a while I do get into trouble there as well and my email and phone number as

41:08

well would love to talk to any of you and yeah I am going to end my

41:16

presentation now and I am going to we’re gonna try to get Scott back on line and

41:23

see if his audio is a little bit better

41:34

all right Scott you hear us you there

41:42

Scott all right looks like Scott’s still having some technical difficulties let’s

41:51

take a look at what questions we’ve got first question is see CCAC use yes we

42:00

have registered for them we expect confirmation any day now the we will send out an email on how you

42:07

can get those CEUs so perfect for that

42:15

next question is around the data layers what data layers to use to create

42:20

management zones for nitrogen like I said my favorite management zone tends

42:27

to be a TB yield data now when I talk about yield data is I don’t take just

42:35

any yield data I work in an area that does have some winter wheat winter wheat loves to have

42:42

find unique ways every year to try to kill itself and so because of that taking the wheat yield data and adding

42:50

that into any algorithm it can be a little bit of a challenge if you want to use that as a historical data layer so

42:57

I’m always a little hesitant to be using wheat idea same with on soybeans soybean very great

43:06

yield data until you get a year when you get a lot of white mold for those of you

43:11

who grow soybeans on 30 inches or on heavy ground or sharps hands it might be very uncommon for you guys to see white

43:18

mold there are areas that grow soybeans on 15 inches or even 7.5 inches and in

43:25

those cases especially it’s a little Grothe or if we start getting on a nice bit of rain you can see white mold start

43:34

to build up and in those cases you can

43:39

have significant yield loss so now all of a sudden your soybean yield data is testing that your best or highest yield

43:50

potential area is actually one of your worst so once again when it comes to data later when I’m talking to

43:57

individuals around the data layer the absolute most important data layer is

44:03

the data layer between your ears it’s the experience you have on that

44:09

farm including the farmer and into the conversation is absolutely critical to

44:16

make sure that you’re taking therefore advantage of that next question is how are recommendations

44:23

made so the recommendations that I use I

44:29

will start off with a fairly limited range of nitrogen rates one of the

44:38

things that I have learned with variable rate uh nitrogen is if a farmer comes to

44:44

me and says listen I want to spend let’s

44:49

say $75 per acre on nitrogen I want to put down a hundred seventy five pounds

44:54

of nitrogen as an average can you help me put that nitrogen in the best

45:00

possible spot yeah I can probably do a fairly decent job of that I need to take

45:05

into consideration what is the the crop what is the soil type what is his

45:10

management what was last year’s crop but I can get a pretty good handle if I’ve got some good management so as to move

45:16

that nitrogen around now that same farmer comes to me and says hey I want

45:23

to maximize my yield what amount of nitrogen should I be putting down that is a very tough question to be able to

45:31

answer because it’s moving year to year the longer that I can hold off to be able to make that nitrogen

45:37

recommendation the better the more confident I’m gonna be but like I said

45:43

now you got this issue is am I going to get rainfall to get it in so for those

45:48

of you who have the ability ability to turn on the rain IE irrigation that is

45:54

going to be a huge asset but if you’re looking for a general idea what I will do is I will

46:03

split a field into either two or three zones and the lower productivity zones

46:10

last third round out always the exception Lester groundout those lower

46:15

productivity zones I usually go about twenty to twenty five pounds above whatever the average is and in the lower

46:22

or in the higher productivity zones where that higher organic matter is where it’s going to mineralize a little

46:27

bit more nitrogen I’m backing down twenty to twenty five pounds that’s where I’m going to start and then I’m

46:33

gonna be testing every year to be able to find to that a little bit further all

46:38

right next question you have a protocol for taking the psmt soil sample cores in

46:46

regards to corn crop row spacing and where the cores are taken great question

46:52

so our approach on this is that we want

46:57

to take a twelve inch that’s the soils that I’m familiar with I’m definitely

47:02

open to seeing different approaches but I’m taking a twelve inch core segment in

47:08

it into both six inches and then some two or six to twelve inches so I’ve got

47:14

a shallow and a deep nitrate test and I am doing that ideally one sample in

47:23

every management zone that I’ve got in that field that’s as a bare minimum if I

47:28

have my choice I want to be able to be taking taking two in each zone takes a

47:36

little bit more time but that is the approach that we use for for psmt timing

47:45

wise on that I try to do it about seven days prior to when the farmer is wanting

47:52

to decide dress my experience with psmt test one of the challenges is you do

47:59

have to keep those samples cold so I’ll make sure that I’ve got a cooler so next

48:09

question are you all – doing variable-rate see prescriptions

48:14

as well so putting more seeds per acre in better management zones that’s I’d changed the nitrogen rate and

48:23

that’s actually coming from me Lee I love that question I am that’s actually where I first cut my teeth on variable

48:30

rate well and that’s actually where the whole validation curves come from is from doing the work with very braid

48:41

planting or variable rate seeding it really started off with variable rate corn and then have moved in Fairburn

48:48

soybeans variable rate edible beans so yes a lot of experience on that that

48:54

actually goes back to the last ten years as a general rule of thumb you because

49:00

you’re asking does that change the nitrogen rate I’m assuming you’re talking with corn it does somewhat not

49:08

as much as you would think actually the bigger piece that comes into play is

49:13

understanding how on your seeding rate is being is being influenced by your

49:20

phosphorus and potassium levels because those phosphorus and potassium levels are going to drive a stock stock

49:27

strength one of the cool parts about how we do very berate validation is those

49:33

chat blocks you can put some pretty cool outlier rates so with the example I always like to use as my father my dad

49:41

likes to push the the envelope so I was putting able to put in these those check locks and those check box about 120 feet

49:47

by 120 feet so about a third of an acre and those check blocks came next year we

49:53

went at 40,000 and a couple of them they were completely flat now most farmers don’t appreciate when

50:02

you would cause your corn or the crop to go completely flat however in that case

50:09

my dad was really glad that he was just dealing with about 6 or 7 check blocks of flat corn instead of having a third

50:17

of his field flat so that is something that I see a lot of value in it is being

50:26

able – to push the envelopes and see how things interact and like Aaron Stefano’s

50:32

who’s with mosaic that I mentioned he’s showing that even variety yes

50:38

sensitivity is a big big part of that all right so that’s all I got all the

50:44

questions there let’s see if we got some

50:50

more questions and it sort of spot would

50:58

like to see an example of one of your prescription algorithms it’s not as private than I understand I don’t like

51:07

any of the ones that I have used in past years Roger I agree with you the best

51:14

algorithm is the one that you buy into and that you can validate like I said if

51:19

you reach out to us I would love to have a chat with you and let’s see if we can build an algorithm

51:25

that works for your farmers or if you’re a farmer for your ground and one that you can feel confident in so yeah we

51:32

will definitely make sure and to work with everyone in anyone who wants to add value to the farm operations that

51:40

they’re involved with and with that we are out of questions and I’ve got two

51:46

minutes to spare before the end of the presentation I take the time now to thank everyone for participating those

51:54

were some great questions and I do a lot of fun sharing what we’re doing on with nitrogen keep an eye on your email I

52:00

know Scott has a bunch more webinars planned and we’ve got some pretty cool

52:06

topics and more data we want to share especially with the cover crop so yeah

52:12

we’ve got really cool stuff on cover crops coming so that’s the teaser and looking forward to talking to you guys

52:18

again soon thanks